Shaun Williams is bringing the future of farming to Springfield.

Picture this: a 320-square-foot shipping container that houses a commercial-scale, hydroponic farm that makes it possible to grow food 365 days a year in any climate.

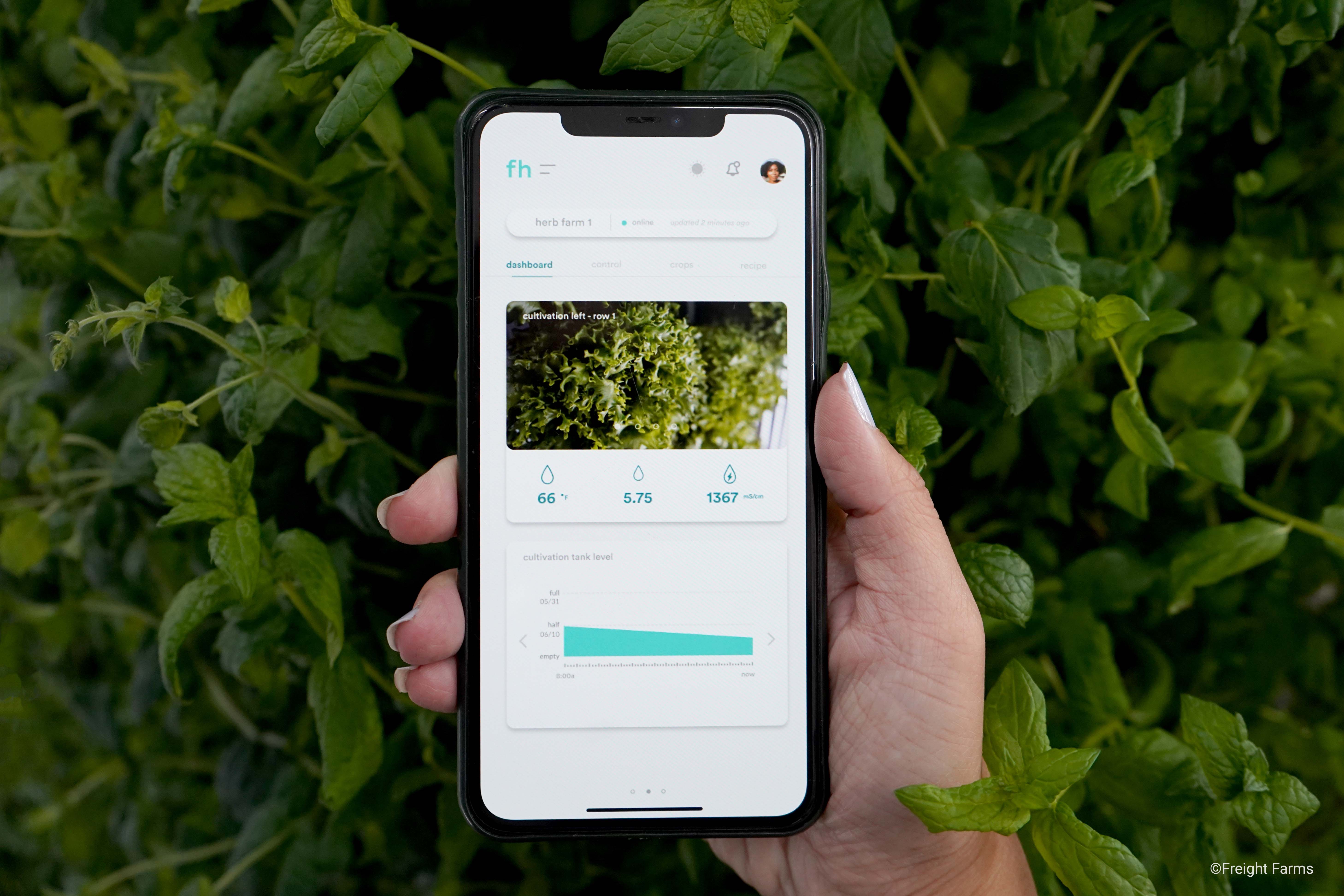

Every plant is hooked up to a sensor system, which allows the farmer to run the farm from their smartphone, controlling the temperature, water usage and light intensity from anywhere with a Wi-Fi connection.

Williams' Oasis Orchard and Farm will be the first to bring Boston-based Freight Farms' proprietary shipping container farms to southwest Missouri. The site, located on Williams' long-time family farm in Halltown, west of Springfield, has been prepped and the first container will be delivered in October, setting the company on a timeline for its first harvest in January, Williams said.

The space savings will be immense compared with traditional farming.

“We're able to grow roughly the equivalent of two-and-half football fields inside of this container,” Williams said by phone, adding that he hopes to eventually purchase two more containers to add to his farm. “We can grow a thousand pounds of lettuce per month per container.”

What smart farming looks like

Freight Farms' proprietary system has two parts, with the first being the container itself, which they call “The Greenery S.” The company has been making vertical farms inside shipping containers since 2012 and has perfected using just about every square inch of the container, which cost $149,000 each, according to its website.

Each container features a state-of-the-art controlled environment due to its protective insulation and uniquely built heating, ventilation and air conditioning units. It sports high-efficiency LEDs that allow light automation and scheduling, even selectively permitting specific wavelengths of light to help plants grow best.

The container features a hydroponic system that runs on less than 5 gallons of water per day. It's so advanced that “even condensation is captured and routed back into the container to water plants,” Williams said.

As well as the 40-by-8 foot container, Freight Farms sells an automation software called Farmhand. The subscription-based software “makes farming smarter and simpler” and costs $2,400 annually.

Imagine an app that shows your farm on a smartphone. You can see and control temperatures, water usage and light automation for each plant, even allowing you to schedule precise cycles from your phone. It will also notify the user when an unexpected change has happened at the farm.

Think about a Peloton exercise bike

Rachel Wisentaner, senior account executive at Freight Farms, said she can't stress how important Farmhand is, comparing the whole system to a Peloton exercise bike, with the container being the bike and Farmhand being the software that streams the classes and forms the community that makes Peloton unique.

“At the end of the day, you're still farming,” Wisentaner said, but the software is “taking a lot of the guesswork out of it and eliminating a lot of risks for our farmers.”

If there's a sudden power outage in the middle of a hot summer day and you're away from the farm, Wisentaner said, you can get a text notification that shows the temperature inside the shipping container has increased dramatically.

“You’ll have to go in person to see what’s going on, but that is huge because, otherwise, without the software, you’d have no idea,” she said. “You could wake up the next morning, go into the farm and experience a whole crop loss.”

Why bring it to west of Springfield?

Williams' farm will be the first in the Springfield region to host a Freight Farms shipping container, Wisentaner said. There are a few others operating in Missouri, but they are in the Kansas City and St. Louis areas.

Williams grew up on the Lawrence County farm in Halltown, which has been in his family since 1947. He milked cows twice a day, every day, throughout his teenage years, he said. His parents still own the farm, while his brother, Cody, runs it day to day.

The farm has had times when it wasn't profitable, and the family had to shift gears to get it out of the red again, Williams said, like when it shifted from a dairy farm to a beef cattle operation in the 1990s. He fears the cattle operation won't be profitable for long and is exploring new revenue sources.

Williams fears his brother, Cody, who is a person with an intellectual disability, will be out of work if the farm runs into financial challenges. Williams hopes to avoid that by starting this new venture with his wife and business partner, Ella Mullokandova. Williams expects the whole family will get involved, including his father, Kenny, and mother, Jeanie.

The timing couldn't be better for the Springfield metro area, which has seen the recent shutdown of Urban Roots Farms in downtown. Williams hopes the restaurants and consumers who relied on Urban Roots for fresh produce will turn to Oasis Orchard and Farm, he said.

“If we're growing here,” Williams said, “we can harvest today and have it at the restaurant tomorrow.”

Hyper-local produce

Williams also emphasized the importance of bringing hyper-local, decentralized produce to Springfield.

“We've all realized during the pandemic that the food supply chain is not where we would want it to be,” he said, adding that 90 percent of produce in the U.S. comes from the West Coast and it takes about three weeks from the time it's picked to land in a Midwest shopping aisle.

To be sure, Williams has eyes on other markets in case Springfield doesn't spur the demand he hopes, he said. He is in talks the manager of Chicken N Pickle, a Kansas City-favorite restaurant that lures customers with the combination of pickleball courts, fried chicken and waffles. Williams hopes Oasis can grow specific produce that Chicken N Pickle demands, he said.

“Each one of these locations are $15 million restaurants,” he said, referring to the two Chicken N Pickle stores in the Kansas City area.

In-depth analysis for users

Freight Farms has a crop science team that publishes detailed reports on the ideal growing environment for specific plants. The reports allow farmers like Williams to skip the experimental stage of farming completely and start with methods that have been proven to be the most effective to grow specific plants. The reports include details on nutrients, light effects, and yield targets, Williams said.

Oasis has about 60 plants the Williams family can immediately start growing, depending on demand, because of the reports by Freight Farms, Williams said. With help from Freight Farms' customer support team, Williams said he is confident the farm will be up and running on time.

Oasis will eventually have its pick of over 500 kinds of crops to grow with detailed reports from Freight Farms, allowing the company a great amount of flexibility, Williams said.

The Boston-based company even has an online store where farmers can partake in a subscription service for growing goods like nutrients, seeds and soils.

Freight Farms has over 600 shipping containers in operation across the world and the company has trained more than 1,000 people to use their system, Wisentaner said. Williams' farm is unique, she said, in that it is bringing the vertical farming system to an existing piece of agriculture.

“We're very excited about Shaun’s business,” she said, adding his openness to technology is a relief. For people who have had a certain type of farming in their family for so long, “there's a lot of fear of moving to a new technology.”